Why Formulations Affect Insecticide Performance

Insecticide formulation technology is vitally important as it enables the same active ingredient to perform in different treatment scenarios.

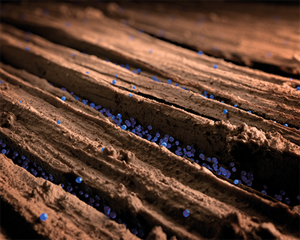

Different residual insecticide formulations make the active ingredients they contain more effective on certain surfaces. Selecting the correct formulation can make the difference between the success or failure of an insecticide treatment.

Formulation types available for insecticide concentrates:

Emulsions in water (EW)

These are very active on non-porous surfaces, but they lack efficiency on porous absorbent surfaces. This is because the active ingredient is dissolved in the formulation, so when applied to non-porous surfaces it gets absorbed where it’s no longer bioavailable to the insects.

Microencapsulated (ME)

These have long residual capabilities if left undisturbed. Once the capsules are ruptured or broken-down the active ingredient gets absorbed into the surface where again it can affect the bioavailability of the active ingredient.

Water soluble granules (WG) and wettable powders (WP)

With this formulation the active ingredient is coated onto a carrier of inert materials, this leads to improved action on porous surfaces. The downside of this is the inert material tends to produce visible white residues on sealed, shiny surfaces (not WG).

Suspension concentrates (SC)

These formulations have been a good compromise for pest controllers and their customers as they don’t leave visible residues, but can show some varying performance on moderately porous surfaces.

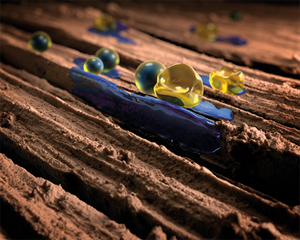

Partix formulation technology

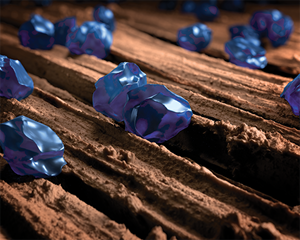

Envu have developed a new, patented formulation concept, which can be found in K-Otherine Partix. This novel formulation is made from special agglomerations of deltamethrin crystals combined with a new inert carrier material. As a result, the formulation particles now reach a size which make them perform consistently well on all surfaces without leaving any visible residues or deposits.

The development of K-Othrine Partix has resulted in several other features which are unique to this formulation.

- As the product particles aren’t absorbed into surfaces, they are more likely to come into contact with insects.

- Active substance molecules are transferred onto passing insects so that the knockdown effects are swift and reliable.

- The active ingredient remains available, and this optimised bioavailability on the Partix formulation leads to a period of effectiveness of up to three months on all tested surfaces.

- At the same time, the level of efficacy is achieved with a lower dose rate of active ingredient. A 50% reduced dose rate delivers the same performance and persistence as a standard deltamethrin SC.

Formulation technology is important not only for product application, but also for product registration. K-Othrine Partix has new registration which has a wide range of pests and locations on the label, including indoors, outdoors, public buildings & industrial buildings enabling control of crawling insects, bed bugs, cockroaches and wasps.

Partix technology incorporates the active ingredient in large, solid particles, giving consistent performance on absorbent surfaces.